services

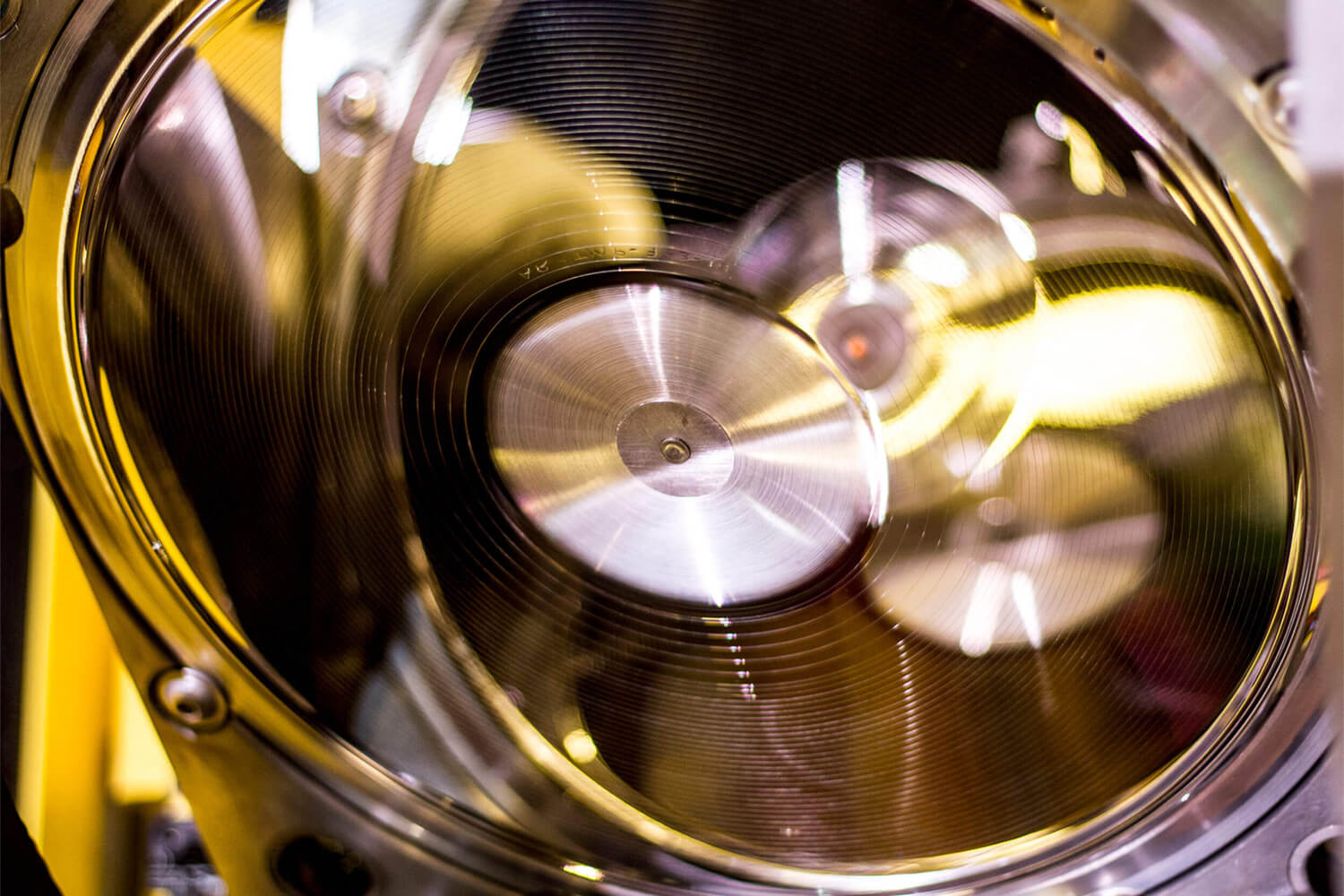

Lacquer Mastering

The first step in the pressing process is lacquer mastering. Third Man Mastering's experienced engineers, located on site here in Detroit, take the mixed and mastered source audio and using a Neumann VMS-70 cutting lathe, cut the grooves of the record into the surface of an aluminium disc coated in a soft lacquer at either 33 ⅓ rpm or 45 rpm.This is the crucial first step in the production process, determining the overall sound of the finished record. To learn more about the lacquer cutting process please visit our FAQ page.

Electroplating

Once lacquers for each side of the record have been cut they'll be sent off to one of TMP's trusted electroplating partners for processing where they will be sprayed with liquid silver and then nickel plated to form the stampers used to press the records.

There are two plating options available, a 2-step and a 3-step process, with the 2-step being the most popular, depending on both the budget and desired pressing quantity of the project. To find out more about the plating stage and processes available, visit our FAQ page. Once the lacquers are processed a set of test stampers will then be sent to TMP to run test pressings prior to production.

Test Pressings

Prior to running production on the full order quantity a small test run will be pressed to verify the quality of the cut and production metal.

After these tests successfully pass through our audio QC department a set of 5 test pressings per record will then be sent out for customer approval. Listening to multiple test pressings helps to ensure the audio quality is consistent from record to record.

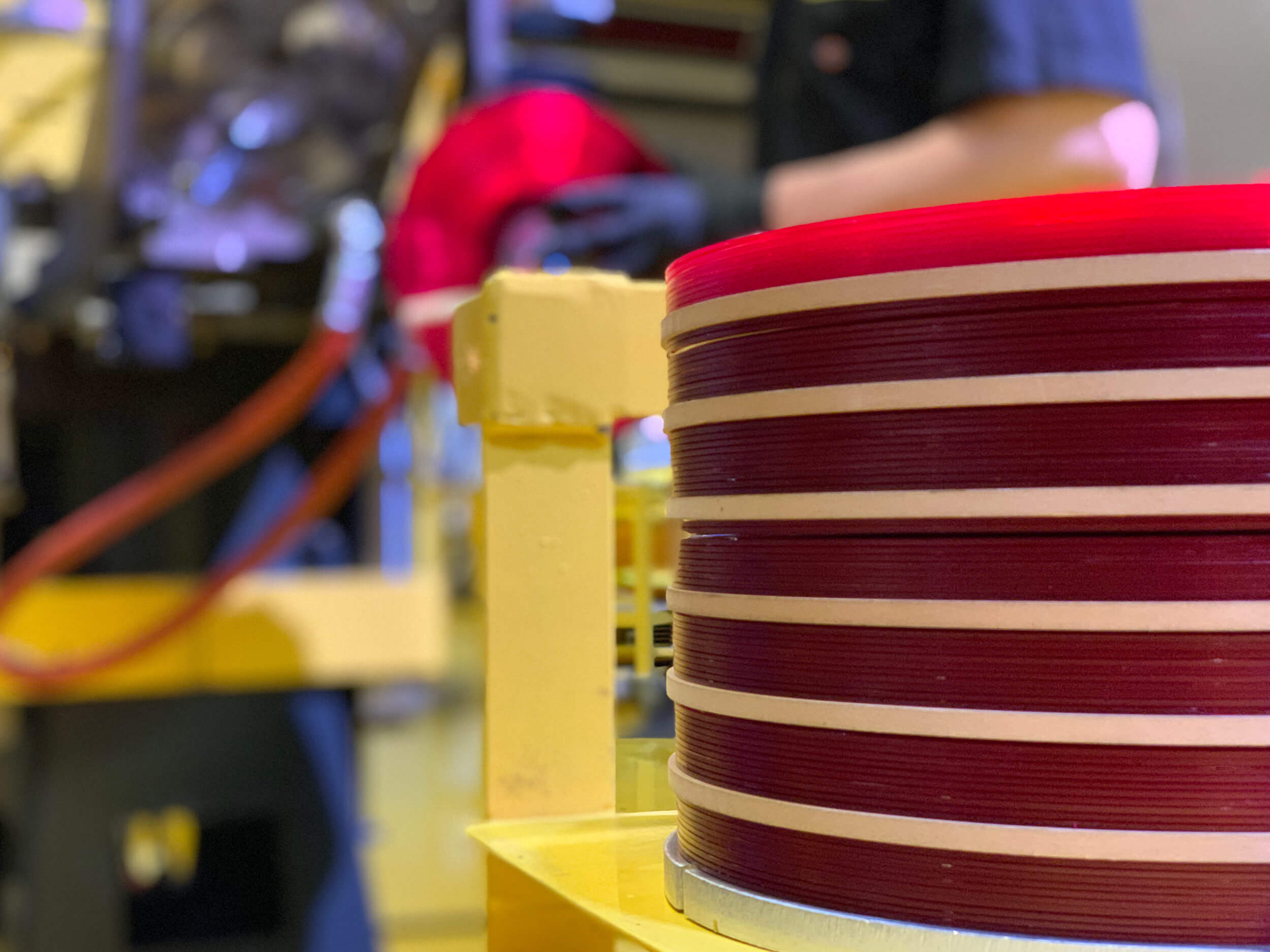

Vinyl Pressing

Once the test pressings have been approved and all packaging components arrive in house the order will then move into full production. Pressings are available in 140g or 180g for 12” LPs and 42g for 7” records. Record manufacturing is quite an involved process requiring very high levels of care and attention to detail at each stage, from dialling in the presses to meet the needs of each order, to the uncompromising audio and visual QC departments inspecting them, ensuring only the highest quality records make it into the careful hands of our packaging team for final assembly. Multiple sets of highly trained eyes and ears closely monitoring each order as it presses allows for real time diagnostics and problem solving resulting in high QC yields and minimizing waste as much as possible.

Packaging

Upon completion on press and in QC the records then move on to the packaging line for final assembly. Here the team carefully collates each individual unit to the order specifications, however involved they might be, ranging from packaging individual 7” singles to more involved multi variant orders or multi component, multi LP box sets, they love a challenge.

Shipping

Once fully assembled the order is then carefully boxed and palletized to the order's predetermined shipping specifications ready to make their way into the hands of the customers and/or distributors.